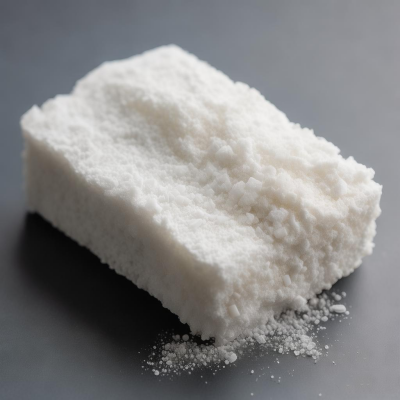

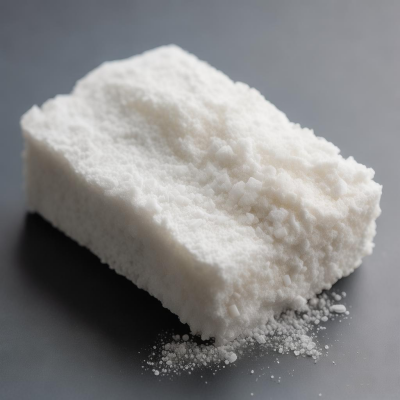

Fumed Silica — A Key Additive for Enhancing Product Performance

Fumed Silica, also known as colloidal silica, is an inorganic compound composed of silicon dioxide. It is produced by the combustion of silane at high temperatures, resulting in a material with an extremely high surface area and low density. Fumed silica is widely used across various industries, including coatings, plastics, cosmetics, and food, due to its unique physical and chemical properties, making it an indispensable component in many formulations.